section-24ca95c

Polishing

Polishing is a combination of several techniques that involve polishing (shiny finish) or buffing (matte finish) metal objects by rubbing them with various different materials (abrasive, cloth, etc.).

The most commonly used abrasive is emery: this is a rock that contains a high content of natural alumina (corundum) but also magnetite, hematite and quartz.

Workshops engaged in the field of polishing receive metal parts (watch cases, straps, jewellery, etc..), blanks or stampings. These parts are left with many marks following these operations: rough patches, burr, weld deposits, etc. These parts need to undergo an “aesthetic treatment” in order to obtain their final lustre.

section-3ef17c4

Polished objects

The watch-making industry employs a large number of polishers,

In particular for finishing the parts forming a watch case, such as:

• Case body

• Case back

• Glass

• Strap links, fasteners…

etc...

But watch-making is not the only sector that uses polishing.

Indeed, this technique is used on numerous high-quality metal products, such as:

• Jewellery

• Lighters

• Pens

• Medals

section-0d8ce9c

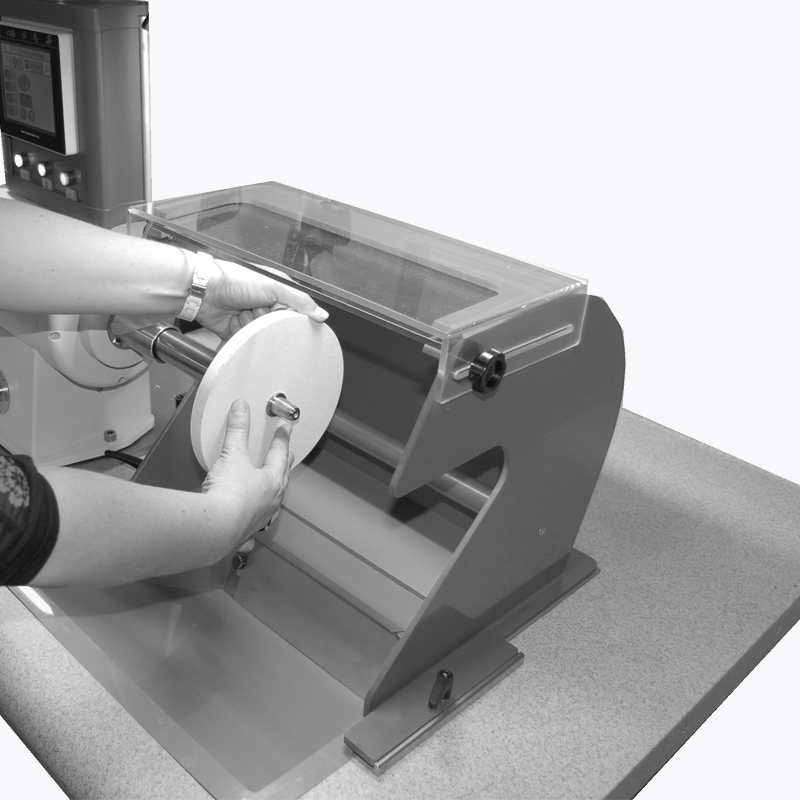

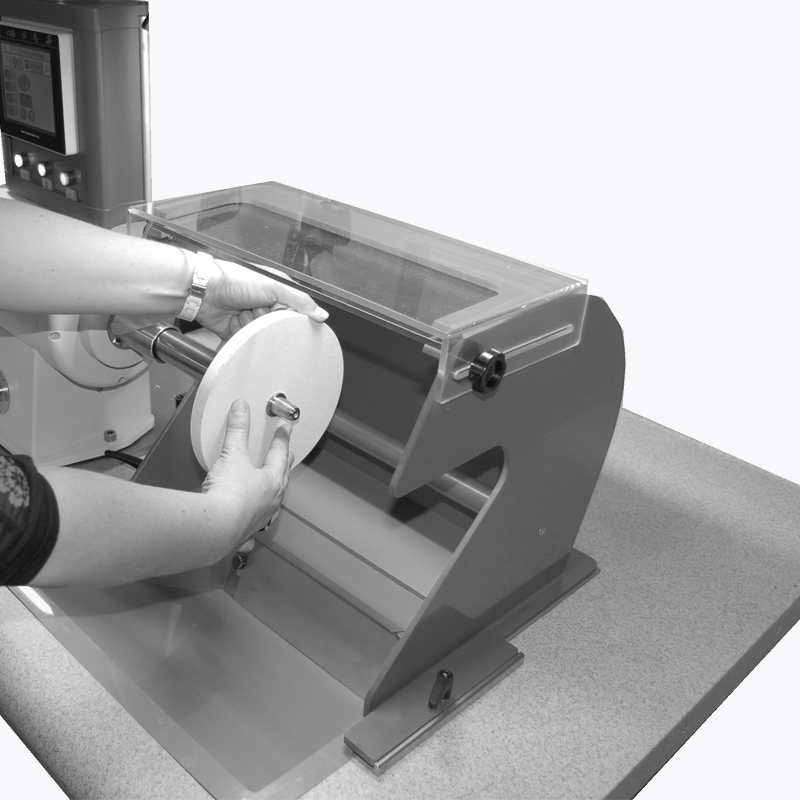

CMP has developed a range of polishing work stations for its customers as well as complementary operations including buffing and satin-finishing in order to meet aesthetic and ergonomic demands, as well as specific functional requirements.

Our polishing tables are designed to the same standard and are available in different configurations:

Single or double station, different polishing tools, lighting, grinding block, foot rests, etc.